پالپینگ محصولی نوآور در اجرای رنگ های ساختمانی و جایگزین سنگ های گرانقیمت ساختمانی

میکروتکست، میکروپالت، پالپینگ، پالپکست، میکروپالپکس محصولاتی نوین و جایگزین رنگ های ساختمانی می باشند.

مزایا:

- قیمت پایین

- کیفیت بهتر

- به صرفه بودن

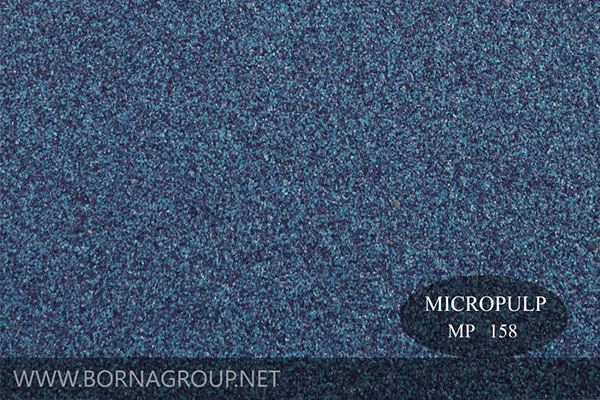

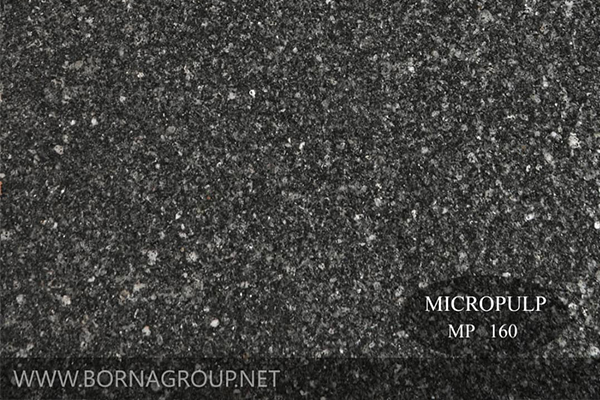

پوشش گرانیتی نما

پوشش گرانیتی نما میکروپالپ متشکل از چیپس های گرانیتی (میکاهای رنگی ریزدانه)، رزین های اکریلیک پایه آب، مواد نانو، مواد نرم کننده جهت جلوگیری از ترک ودیگر افزودنی ها به سبب بالا بردن مقاومت رزین ها و همچنین چسبندگی میکاها بر روی سطح است. این محصول که دقیقا مشابه پالپینگ می باشد فقط بافت ریزتری دارد و از جمله تفاوت ها یا مزایای آن می توان به پوشش دهی بالاتر نسبت به پالپینگ اشاره نمود و همچنین میکرو پالپ قابلیت اجرا با غلطک و رولر را نیز دارا می باشد.

آکرو پالپ زیر مجموعه ی میکروپالپ می باشد با این تفاوت که در میکرو پالپ قابلیت ترکیب میکاهای رنگی وجود دارد و یک محصول می تواند با دو تا چند رنگ میکا مخلوط و عرضه گردد ولی در آکرو پالپ همانند رنگ های آکرولیک رنگ ها به صورت تک رنگ عرضه می گردد ولی مواد دارای میکاهای ریز دانه می باشد که مقاومت رنگ اکریلیک را چندین برابر می کند. توضیحات محصول میکروپالپ محصول میکروپالپ متشکل از سنگ طبیعی میکا، در سایزهای ۰ تا ۲ میلی متر و به ضخامت حدود ۲۰۰ میکرون که با رنگ های پلی یورتان کوتینگ می گردد و با رزین های اکریلیک پایه آب و دوستدار محیط زیست (اکثر متریال ها آلمانی هستند) و با چسبندگی بالا و نفوذ پذیری در سطح زیرین، مخلوط می گردد، پس از اعمال محصول بر روی ترجیحا سیمان نرمه و خشک شدن، ۱۰۰% قابل شستشو خواهند شد . در موارد و مناطقی که نور خورشید بسیار داغ و مستقیم و مخرب است بهتر است از رزین های پیور اکریلیک که مقاومت یووی بالاتری دارد، استفاده گردد.

مواد آماده اجرا (گزینه۱) فقط باید با یک میکسر مناسب مخلوط گردد و با پیستوله کنیتکس پاش با سوراخ نازل ۴ تا ۶ میلی متر به کمک کمپرسور هوا برروی سطح به صورت آستر و رویه اعمال گردد و همچنین می توان با غلطک رنگ نیز اجرا نمود ولی مصرف مواد حدود ۳۰ درصد افزایش پیدا خواهد کرد. مواد غلیظ (گزینه۲) باید ابتدا با آب تیلوز ( پودر تیلوز آلمانی) که به همراه محصول ارسال می گردد رقیق گردد (روش تهیه آب تیلوز: به ازائ هر ۱۰ لیتر آب ۱۰۰ گرم پودر تیلوز از یک روز قبل از اجرای کار به آب اضافه و مخلوط می گردد و پس از به اصطلاح بازشدن تیلوز به ازای هر بشکه ۶۵ کیلوگرمی حدود ۵ تا ۸ لیتر آب تیلوز از قبل آماده شده به مواد اضافه و کاملا میکس می گردد).

مواد باید در دمای بالای ۵ درجه نگهداری و اجرا گردد در صورت یخ زدگی مواد داخل ظرف و یا بر روی دیوار تا قبل از خشک شدن، رزین خاصیت خود را از دست داده و میکاهای رنگی ریزش پیدا خواهد کرد. زیر کار مواد باید تمیز و بدون گرد و غبار باشد و در موارد سازه های قدیمی با سطحی کثیف باید سطح با واترجت شستو گردد و بهتر است جهت زیر کار از پرایمر استفاده گردد. مزایای میکروپالپ 1) پوششی زیبا با بافتی ریز 2) پوششی یکپارچه و ضد آب 3) مقاوم در برابر اشعه ماورابنفش خورشید untiuv 4) سرعت اجرایی بالا 5) مقاومت حرارتی بسیار بالا بخاطر وجود سنگ طبیعی میکا (نقطه ذوب میکا بالای ۱۲۰۰درجه سانتی گراد) 6) وزن کم و قیمت مناسب نسبت به سنگ 7) آنتی باکتریال 8) پوشاننده ترک های ریز زیر کار 9) و…